Opis produktu:

Wielowarstwowy dysk cyrkoński to zaawansowany materiał stomatologiczny zaprojektowany specjalnie dla laboratoriów stomatologicznych poszukujących wysokiej jakości, niezawodnych i estetycznie lepszych rozwiązań ceramicznych.Zaprojektowane tak, by spełniać rygorystyczne wymagania nowoczesnej restauracji zębów, to wielowarstwowe ceramiczne pustkowie oferuje wyjątkową wytrzymałość, trwałość i wszechstronność, co czyni je idealnym wyborem do wytwarzania koron, mostów,i inne protezy dentystyczne z precyzją i łatwością.

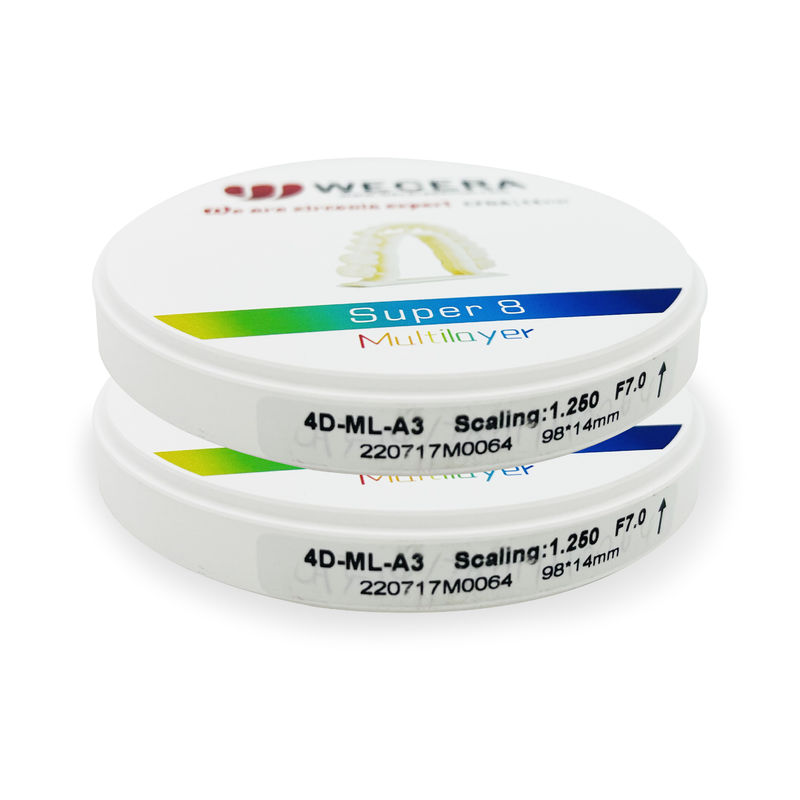

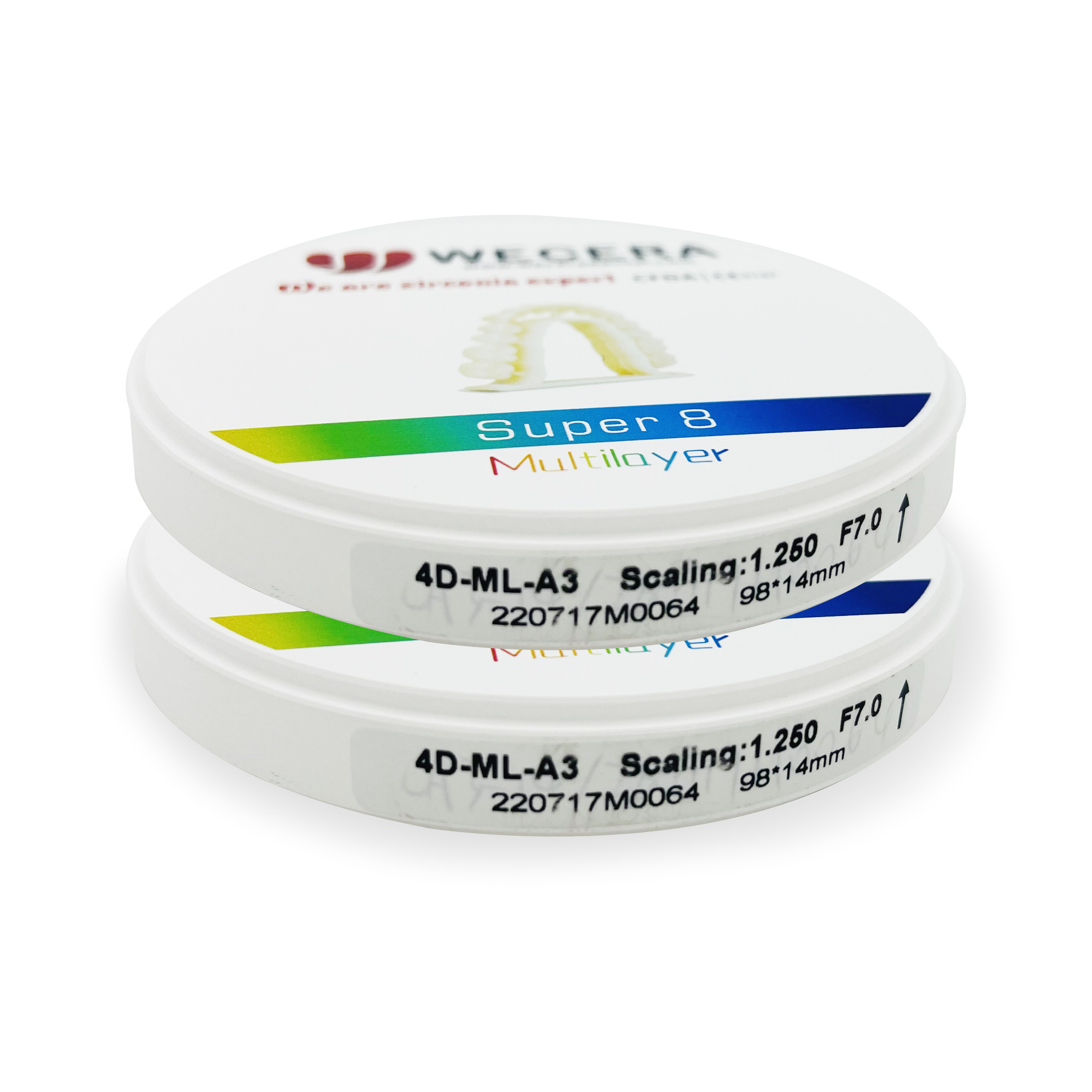

Z średnicą 98 mm, ta wielowarstwowa tarcza z cyrkonem jest zoptymalizowana pod kątem kompatybilności z szeroką gamą frezarek, w tym systemami Roland, VHF i imes-icore.Zapewnia to płynną integrację z istniejącymi przepływami pracy w laboratorium stomatologicznymWymiary i konstrukcja dysku umożliwiają efektywne wykorzystanie materiałów, minimalizując odpady przy jednoczesnym maksymalizacji produkcji.

Jedną z najważniejszych cech tego wielowarstwowego dysku jest jego starannie zaprojektowana wielowarstwowa struktura.zapewniając bardziej realistyczną przejrzystość i gradient koloruW rezultacie odbudowy nie tylko idealnie pasują, ale również wyglądają niesamowicie naturalnie, znacząco poprawiając zadowolenie pacjenta.Wielowarstwowa konstrukcja przyczynia się również do wytrzymałości i odporności materiału, zapewniając długotrwałe odnowy odporne na codzienne zużycie.

Temperatura spiekania wymagana dla tej ceramiki jest 1500 stopni Celsjusza, co zapewnia optymalne zagęszczenie i krystalizację materiału cyrkoniowego.Właściwe spiekanie przy takiej temperaturze zwiększa właściwości mechaniczne tarczy, co daje lepszą twardość i wytrzymałość na pęknięcia.które są kluczowe dla osiągnięcia konsekwentnych i precyzyjnych odnowień zębów.

Powierzchnia płytki wielowarstwowej z cyrkonu jest starannie wykończona, aby była gładka, ułatwiając łatwe frezowanie i zmniejszając zużycie narzędzi podczas procesu wytwarzania.Gładkie wykończenie powierzchni nie tylko poprawia wydajność obróbki, ale również przyczynia się do jakości ostatecznej restauracji poprzez minimalizowanie wad powierzchni i zwiększenie ogólnej estetykiLaboratoria stomatologiczne docenią łatwość obsługi i przetwarzania tej płyty, pozwalając technikom skupić się na dostarczaniu doskonałych wyników.

Zaprojektowany wyłącznie do stosowania w laboratorium stomatologicznym, ten wielowarstwowy ceramiczny pustki spełnia najwyższe standardy branżowe dotyczące biokompatybilności i bezpieczeństwa.Jego skład z cyrkonu jest znany ze swojej doskonałej kompatybilności z tkankami jamy ustnej, zmniejszając ryzyko wystąpienia działań niepożądanych i zapewniając komfort pacjenta.wspieranie szerokiego zakresu zastosowań odbudowy.

Podsumowując, wielowarstwowy dysk cyrkoński to najwyższej klasy materiał stomatologiczny, który łączy w sobie zaawansowaną wielowarstwową technologię cyrkońską, optymalne wymiary,i wysokiej wydajności atrybuty, aby zaspokoić potrzeby nowoczesnych laboratoriów stomatologicznychJego średnica 98 mm i kompatybilność z wiodącymi fresownikami, takimi jak Roland, VHF i imes-icore, czynią go wszechstronnym i wydajnym wyborem do wytwarzania restauracji zębów.Temperatura spiekania 1500 stopni zapewnia maksymalne właściwości materiałuJako wielowarstwowy ceramiczny płaszcz, produkt ten zapewnia wyjątkową estetykę, wytrzymałość i biokompatybilność.Pomaganie laboratorium stomatologicznemu w tworzeniu wyjątkowych operacji odbudowy, które zwiększają wyniki i zadowolenie pacjentów.

Charakterystyka:

Wprowadzenie na rynek pierwszego na świecie 8-warstwa wielowarstwowego cyrkonu, zaprojektowanego tak, aby zapewniać bezbłędny i bezproblemowy wygląd z większą liczbą warstw.Ten zaawansowany materiał stanowi znaczący przełom w technologii stomatologicznej.

Specjalnie opracowany do 14 jednostek mostów dentystycznych, ten cyrkonium osiąga imponujący wskaźnik sukcesu zbliżający się do 100%. Jego innowacyjny projekt zawiera stopniowe zmiany w wytrzymałości, kolorze,przejrzystość, i twardość, płynne przejście z obszaru szyjki macicy do krawędzi nacięcia.

Jako światowy lider w produkcji 8-warstwowego cyrkonu z 15 precyzyjnie dopasowanymi gradientami, ten produkt oferuje niezrównaną naturalną estetykę wraz z wyjątkową trwałością.ustanowienie nowego standardu w dziedzinie środków odbudowy zębów.

Zastosowanie:

Wecera 8-warstwowy wielowarstwowy dysk cyrkoniowy to zaawansowany materiał stomatologiczny zaprojektowany specjalnie do zastosowań koronowych i mostkowych.Ten wielowarstwowy ceramiczny pustki oferuje wyjątkową jakość i niezawodność dla specjalistów stomatologicznychZ średnicą 98 mm i imponującą wytrzymałością 1200 MPa, ta wielowarstwowa oksyda gwarantuje trwałość i długotrwałą konserwację.

Jednym z kluczowych miejsc zastosowania wielowarstwowego dysku z cyrkonu wecera jest w laboratoriach i klinikach stomatologicznych, gdzie precyzja i estetyka są najważniejsze.Gładka powierzchnia dysku i 57% przezroczystość sprawiają, że jest idealny do wytwarzania naturalnie wyglądających koron i mostów, które bezproblemowo łączą się z istniejącymi zębami pacjentówJego wielowarstwowa struktura umożliwia stopniowe przejścia kolorystyczne, zwiększając rzeczywisty wygląd protezy dentystycznej.

Ze względu na wyższą wytrzymałość i przezroczystość, ten wielowarstwowy oksydowy dysk jest idealny zarówno do przednich, jak i tylnych rekonstrukcji,zapewniając niezbędną wytrzymałość do żucia przy jednoczesnym zachowaniu atrakcyjnego wygląduTechnicy stomatologiczni mogą wykorzystać ten produkt do tworzenia wysokiej jakości, niezawodnych restauracji, które spełniają rosnące wymagania dotyczące estetycznych i funkcjonalnych rozwiązań stomatologicznych.

Ponadto wielowarstwowy dysk z cyrkonu wecera nadaje się do stosowania w frezarkach CAD/CAM, wspierając wydajne i precyzyjne procesy produkcyjne.Jego opakowanie jednego dysku na pudełko zapewnia wygodne obsługiwanie i przechowywanie. Dzięki minimalnej ilości zamówienia tylko jednego dysku i możliwości dostawy 100 000 dysków miesięcznie, produkt ten obsługuje zarówno małe, jak i duże potrzeby produkcji stomatologicznej.

Czas dostawy wynosi zazwyczaj jeden tydzień, zapewniając szybkie rozwiązanie dla specjalistów stomatologicznych wymagających terminowych dostaw.umożliwiające elastyczność różnych uzgodnień zakupowychOgólnie rzecz biorąc,Wecera 8 warstw wielowarstwowy dysk z cyrkonu jest doskonałym wyborem dla specjalistów od stomatologii poszukujących niezawodnego wielowarstwowego ceramicznego pustego z wyjątkową wydajnością w koronie i mosty restauracji.

Dostosowanie:

WeCera oferuje najwyższej klasy, wielowarstwowe oksydy z naszego 8-warstwowego, wielowarstwowego modelu z cyrkonu, zaprojektowanego, by spełniać różnorodne potrzeby restauracji zębów.Nasz wielowarstwowy dysk z cyrkonu zapewnia wysoką jakość i bezpieczeństwoKażda z nich jest wykonana z najwyższej jakości materiału cyrkoniowego, o imponującej przezroczystości 57% dla naturalnej estetyki w zastosowaniach korony i mostu.

Nasze dyski są dostępne w różnych grubościach, w tym 10 mm, 12 mm, 14 mm, 16 mm, 18 mm, 20 mm, 22 mm i 25 mm, aby spełnić różne wymagania w zakresie odbudowy.Z trwałością do 100 latOpakowanie jest wygodne z 1 dyskiem na pudełko, a utrzymujemy zdolność dostaw 100 000 dysków miesięcznie.

Minimalna ilość zamówienia wynosi 1 płytkę, a ceny mogą być negocjowane zgodnie z potrzebami Twojej firmy.Wybierz wielowarstwowy dysk z cyrkonii firmy WeCera dla doskonałej wydajności i dostosowania do potrzeb w restauracjach zębów.

Wsparcie i usługi:

Nasze wielowarstwowe dyski z cyrkonu są zaprojektowane, aby zapewnić wyższą wytrzymałość i estetykę dla restauracji zębów.sinterujące, i kończą.

Przy frezowaniu należy stosować odpowiednie narzędzia i parametry w celu uniknięcia rozszczepienia lub pęknięcia dysku.

W celu uzyskania maksymalnej gęstości i przezroczystości, dyski z cyrkonium należy spieniężyć zgodnie z określoną temperaturą i czasem trwania.

Po spiekaniu należy ostrożnie wypolerować powierzchnię, aby poprawić jej gładkość i estetyczny wygląd.

Przechowywać dyski w suchym i czystym środowisku, aby zachować ich integralność i wydajność.

Jeśli wystąpią jakiekolwiek problemy z produktem lub wymagają Państwo pomocy technicznej, proszę zapoznać się z instrukcją obsługi produktu lub dokumentacją obsługi technicznej, aby uzyskać wskazówki dotyczące rozwiązywania problemów i szczegółowe instrukcje.

Zobowiązujemy się do zapewnienia wysokiej jakości wsparcia i usług, aby zapewnić Państwu zadowolenie z naszych wielowarstwowych dysków z cyrkonu.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!